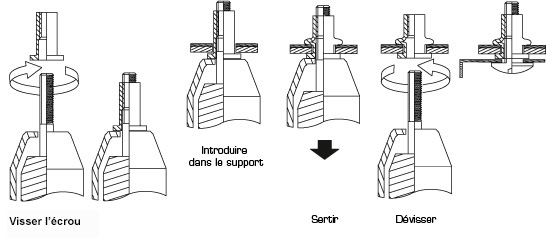

1-Screw the nut on the tool’s mandrel.

2-Insert the nut into the assembly.

3-Set the nut.

4-Unscrew the mandrel.

The set nut is thus ready to receive a screw.

The Blind Rivet Nuts : technical datas

INSTALLATION DESCRIPTION

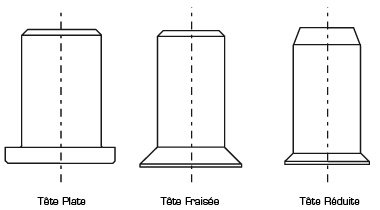

THE DIFFERENT HEAD SHAPES

Flat Head (Tête Plate)

This is the most common multi-purpose head.

Countersunk Head (Tête Fraisée)

It often requires milling the support surface. The countersunk head will therefore be used when needing a reduced space between assembled parts and when a reduced head cannot be used.

Reduced Head (Tête Réduite)

Can be used when needing no or reduced space between assembled parts. Reduced heads can replace countersunk heads because they don't require milling, but they should not be used:

- if the tolerance of the hole is not controlled,

- if the support material is malleable (risk of head extraction)

- if the screw is under bending stress.

Large Head

Upon request.

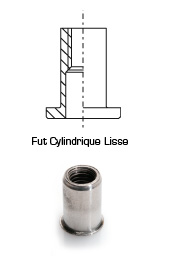

THE DIFFERENT SHAFT FORMS

Cylindrical Smooth Shaft

Common use.

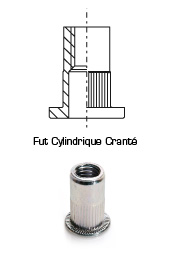

Cylindrical Knurled Shaf

To work on soft materials. Shaft design with positive locking anti-rotation device.

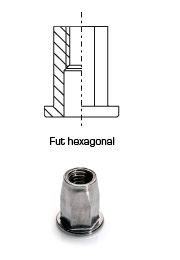

Hexagonal shaft

Provides anti-rotation. Suitable for frequent screwing and unscrewing.

Semi-hexagonal shaftl

Unlike the entirely hexagonal shaft, it prevents any unscrewing of the nut with a wrench (which damages the support surface) after installation.

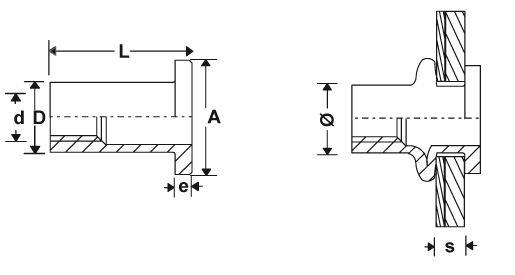

DIMENSIONAL CHARACTERISTICS

| L (mm) | Length |

| A (mm) | Diameter of the head |

| e (mm) | Head Thickness |

| D (mm) | Shaft diameter |

| d (mm) | Thread diameter |

|

Drilling diameter (mm) ø |

|

Grip range (mm) S |

MECHANICAL CHARACTERISTICS

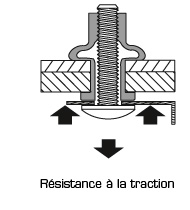

Tensile strength

Tensile strength is the maximum force a nut can bear under axial pressure before breaking (value expressed in Newtons).

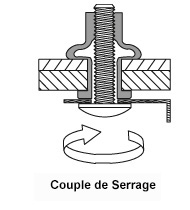

Tightening torque

To measure the tightening torque, the nut is placed on a test plate with a steel washer restrained from rotation, then the screw is tightened (value expressed in Newtons).

| GOFIX - GOSERT TENSILE STRENGTH (N) | |||

|---|---|---|---|

| Ø | ALU | STEEL | STAINLESS ST |

| M3 | 2 600 | 4 300 | 3 800 |

| M4 | 3 900 | 6 500 | 6 200 |

| M5 | 5 900 | 8 000 | 11 600 |

| M6 | 8 600 | 12 000 | 16 300 |

| M8 | 10 200 | 22 200 | 18 800 |

| M10 | 14 000 | 28 650 | 39 800 |

| M12 | - | 35 700 | - |

Indicative minimal values submitted to variations

Note: 1kg = 10 Newton

Note: 1kg = 10 Newton

| GOFIX - GOSERT CLAMPING FORCE (Nm) | |||

|---|---|---|---|

| Ø | ALU | STEEL | STAINLESS ST |

| M3 | 0,7 | 1,0 | 1,5 |

| M4 | 2,5 | 4,0 | 7,0 |

| M5 | 5,0 | 7,0 | 14,0 |

| M6 | 8,0 | 14,0 | 22,0 |

| M8 | 20,0 | 24,0 | 32,0 |

| M10 | 25,0 | 40,0 | 54,0 |

| M12 | - | 70,0 | - |

Indicative minimal values submitted to variations

Note: 1kg = 10 Newton

Note: 1kg = 10 Newton