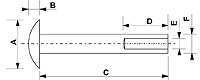

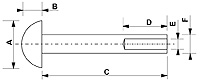

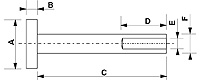

Semi-tubular rivets are similar to solid rivets except that they have a partial hole at the tip (opposite the head). The purpose of this hole is to reduce the amount of force needed for riveting. The power needed to apply a semi tubular rivet is about 1/4 of the amount needed to apply a solid rivet.

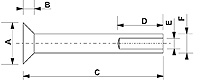

Semi-tubular rivets can also be used as pivots (for a mobile joint) since the swelling of the rivet only occurs at the tail. Tubular rivets go through an additional step during cold-forming process : a cylindrical hole will drill the rivet from end to end.